where : ibrtses embedded

AVR RC Oscillator calibration to an XTAL

A recent project required me to work with an RC driven Mega169P. The setup

just had the RC plus a 32kHz Quarz. The calibrateable RC oscillator has a

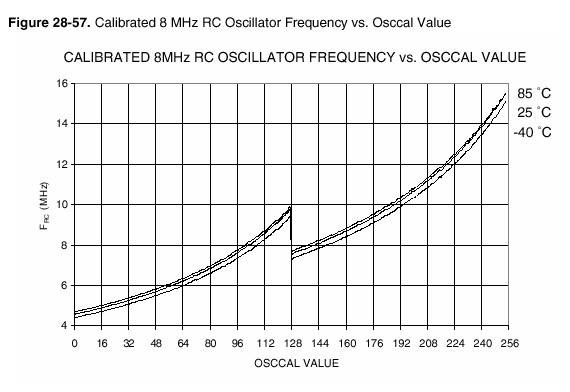

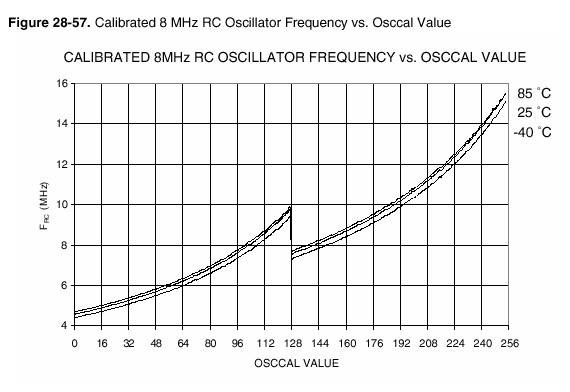

tuning graph as

Taken fom the Mega169P manual 8018I-AVR-11/06, page 363

and I wanted to have the clock at the either timing convenient 8MHz or at

the baudrate convenient 7.3728MHz. First came the manual approach

manual frequency tuning

The manual tuning is not that hard. Have a 16bit timer running to produce say 10ms if it

was running at the desired frequency. Then either poll the timer overflow flag (or have

an interrupt) and toggle a pin. On the scope measure the pin and edit the value until the

period matches.

Since the scope doesn't have the correct resolution, the following code uses two timers

against each other. One as reference, the other for the Osc. It initializes the two timers,

timer2 for the 32kHz XTAL and timer0 for the supposed 10ms tick. The 32kHz clock produces

pulses at 1Hz, which are compared to the 10ms tick. Any other combination is also thinkable.

// timer0 is the 10ms tick from the 7.3728MHz or 8MHz Clock

// This is the 10ms system tick

SetupTimer0:

ldi temp,0x05 ; clk div 1024 = 128us @8MHz

sts TCCR0,temp ; or 138.8us @7.3728MHz

ldi temp,184 ; 256-78 for 10ms @8MHz

sts TCNT0,temp ; or 256-72 for 10ms@7.3728MHz

ret

// Setup timer2 for 1Hz and enable timer0

//

CalibrateManual:

ldi temp,0x44 ; for 7.3728MHz ** enter this

sts OSCCAL,temp ; value manually **

ldi temp,0 ; Timer2 off

sts TCCR2A,temp

ldi temp,0x07 ; div 1024

sts TCCR2A,temp

ldi temp,223 ; 255-32 for 1 Hz

sts TCNT2,temp

ldi temp,0x08 ;

sts ASSR,temp

ldi temp,0x01 ; enable Timer0

sts TIMSK,temp

ret

Why are two procedures above ? The Tick ist used anyway, The CalibrateManual

is replaced by intializing the OSCCAL in the normal Init. Now the interrupts.

They both basically just reload the counters, and toggle a pin. The pins are

from the application unused pins.

interrupt timer0

push ...

ldi temp,184 ; 256-72 for 10ms

sts TCNT0,temp

sbi PORTB,6 ; make a pulse

cbi PORTB,6

pop ...

iret

interrupt timer2

push ...

ldi temp,223 ; 255-32 for 1 Hz

sts TCNT2,temp

sbi PORTE,6 ; make a pulse

cbi PORTE,6

pop ...

iret

I has been shown by calibarting different units of the same hardware, that the

values for OSCCAL are almost independent on the voltage, a bit dependent on the

temperature, but very dependent on the specific controller itself. While for

one example the value was 0x44, with another, it was 0x5C. This means there is

no simple factory preset solution. This led to the automatic tuning described

now. Yes, a thinkable intelligent programmer could do a calibration itself.

Such a solution would then be dependent on the supply- and temperature condition

during the programming.

automatic frequency tuning

This version of the automatic tuning is done at powerup once. It starts with the

OSCCAL at the lowest and increases until the period is short enough. Here, to have

a sufficiently quick calibration the XTAL runs in an overflow mode, meaning it counts

from 0 to 255 and sets the overflow flag every 7.8125ms. While the timer2 counts

round, the software loop counts number of loops it can do incrementing a 16 bit

counter. At approximate 9000 counts per period, the resolution is sufficiently fine.

Before it is forgotten, the interrupts are disabled here.

If the temperature and supply conditions change considerably such that the UART

is not operating reliably anymore, another dynamic, meaning periodic calibration

will have to be considered.

CalibrateRC:

ldi temp,0

sts OSCCAL,temp

; init Timer2 as Async Timer

ldi temp,0 ;Timer2 off

sts TCCR2A,temp

ldi temp,0x08 ;Timer2 Async

sts ASSR,temp

; ldi temp,0x02 ;timer2 div 8, on

; sts TCCR2A,temp ; overflow every 62.5ms

ldi temp,0x01 ;timer2 div 1, on

sts TCCR2A,temp ; overflow every 7.8125ms

OptLoop1:

ldi ZL,0

ldi ZH,0

waitcrc1:

in temp,TIFR2

andi temp,0x01

breq waitcrc1

; sbi PORTB,6 ;debug ******

; cbi PORTB,6 ;debug ******

ldi temp,0x01

out TIFR2,temp

waitcrc2: ; counting loop takes 6 cycles

adiw ZH:ZL,1 ; thus countin target is 9600

; wait for here

in temp,TIFR2

andi temp,0x01

breq waitcrc2

; sbi PORTB,6 ;debug ******

; cbi PORTB,6 ;debug ******

ldi temp,0x01

out TIFR2,temp

; ldi temp,0x62 ;send 0x62 through the UART

; sts UDR,temp

; compare the Z with 9600

cpi16 ZL,ZH,9600

brcc OptEnd

; still too low

lds temp,OSCCAL

inc temp

sts OSCCAL,temp

rjmp OptLoop1

OptEnd:

ret

The optionally inserted 0x62 for the UART serves as visual

check for the scope.

There are a few more thinkable solutions, all of which are rather simple and take

just a few ASM lines. They provide a working, calibrated RC oscillator with little

effort.

Yes, before it is forgotten. Atmel has an Appnote, AVR053, where the STK500 or so

does that. There is another Appnote AVR055, where they also use a 32kHz Quartz for

the RC calibration. They have the focus rather on quickness and operate with binary

seaches for a quick calibration and use in the order of 300 bytes for that, about 5

times more than the above solution.

The above outlined calibration freely uses timer resources, and this is less of a

problem in a bootloader. To the contrary, this is hardly doable in an application.

A dynamic calibration has to be made to fit into the application. A serially serving

device (always able to receive) can never have the baudarte too far off. Changing

the interrupt behaviour require carefull considerations. We either haven't gone this

far, or didn't consider publishing it yet.

Comments are welcome.

Questions ?

Suggestions?

Feedback ?

sponsored links

home

the embedded pages

the AVR pages

last updated 21.oct.07, or perhaps later

Copyright (99,2007) Ing.Büro R.Tschaggelar